Prozess-FMEA: Präventive Risikomaßnahmen für Offshore-Windparkprojekte

DIMAS, J. (2015):

Process FMEA: Preventive Risk Measures for Offshore Wind Farm Projects.- Proceedings of the German Wind Energy Conference DEWEK 2015 (Bremen, Germany, 19.-20. May 2015), 4 pages.

Download

Zusammenfassung

Diese Konzeptstudie beschreibt die Entwicklung Process Failure Mode and Effects Analysis (P-FMEA, in Deutsch: Prozess-Fehler-Möglichkeits- und Einfluss-Analyse) für das präventive Qualitäts- und Risikomanagement von Offshore-Windparkprojekten. Das Design folgt den besonderen Anforderungen des bauherrenseitigen Projektmanagements.

Als vorbeugende Maßnahme sollte die (erste) FMEA in einem frühen Projektstadium durchgeführt werden, um die Ergebnisse bereits in der Ausschreibungsphase und in den Vertragsverhandlungen berücksichtigen zu können.

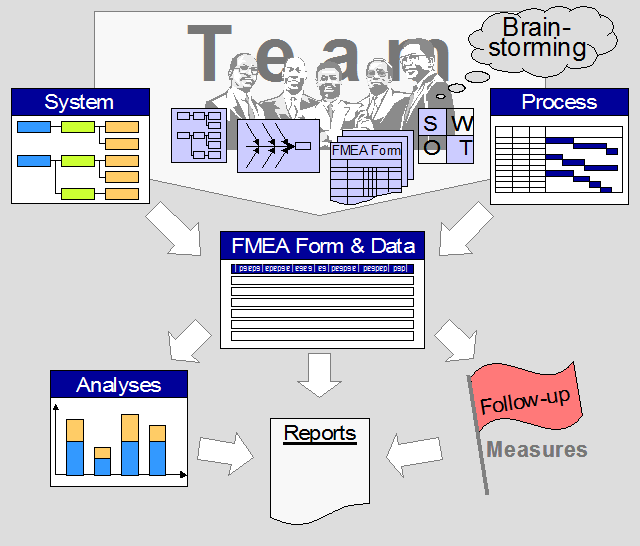

Um die Eingabe, Verarbeitung, Analyse, Dokumentation und Darstellung der Daten zu unterstützen, wurde eine Makro-basierte Tabellenkalkulationsanwendung (FMEA-Tool) entwickelt. Die Ergebnisse sind als Eingangsgrößen für das technische und kaufmännische Risikomanagement geeignet.

FMEA-Einführung

Poster zum Text

Process FMEA: Preventive Risk Measures for Offshore Wind Farm Projects

Abstract

This concept study describes the design of a Process Failure Mode and Effects Analysis (P-FMEA) in order to promote the preventive quality and risk management for offshore wind farm projects. The design follows the special demands of the client's project management.

To support the input, processing, analysis, documentation, and presentation of all data, a macro-based spreadsheet application was developed (FMEA-tool). The results are suitable for further processing by technical and commercial risk control.

Introduction: Project Related Risk Management

Several project developers have already gained extensive experience with the installation of offshore wind farms and have been faced with a significant amount of major failures in various contract packages. One lesson learned by the project companies is to go for a higher vertical integration of risk tracing. Even if certain risks are contractually shifted onto contractors, liability limitations usually do not allow the full recovery of heavy losses. Moreover, a simple contractual transfer of risks sometimes makes it even harder to intervene, if necessary.

Even first-hand experience with recent failures does not necessarily mean having suitable prevention measures for future incidents in place. Moreover, the next project would most probably employ different contractors and feature new technologies. Even the company's project team might have changed.

Therefore, a systematic and sustainable approach to identify and deal with risks is essential for a company's learning curve and also increases the confidence of the stakeholders in an improved control of project risks.

Such a systematic approach is provided by the Failure Mode and Effects Analysis (FMEA) method. The method was developed by NASA during the Apollo-Project [1]. Other sources trace its origins to the US Armed Forces [2]. Nowadays, several FMEA types are well established within the aviation, automotive, and other industries.

Experience demonstrates that initial project planning consists of hundreds of processes which subsequently diversify into thousands of sub-processes. As a consequence, a macro-based spreadsheet application has been developed (FMEA-tool) to guide the FMEA team through a structured process in order to deal with such a large quantity of data.

Corresponding poster publication

Process FMEA: Preventive Risk Measures for Offshore Wind Farm Projects

FMEA-Einführung in Deutsch

Quellen

[1] PFEUFER, H.-J. (2002): Fehler-Möglichkeits- und Einfluss-Analyse (FMEA).- 81 S., Symposion Publishing GmbH (Düsseldorf).

[2] EILERS, J. (2008): APIS IQ-Software (Entwurf vom 28.11.2008).- 148 S., www.apis.de/pub/docs/book/apis_iq_software_de.pdf, 26.04.15.